It’s a very rare occasion that we manage to get three brand new Bar Crusher 670 Hardtops in the same place at the same time.

A couple of weeks ago, the plan came together with the organisation of Rod Elliot from AMC and his staff to take these boats out for a combined water test and review to document their performance.

Prior to delivery of any new Bar Crushers, thorough tests are carried out to ensure the new owners of the boats are getting exactly what they pay for.

I was asked to go along during these tests to photograph and document just how incredible these boats are.

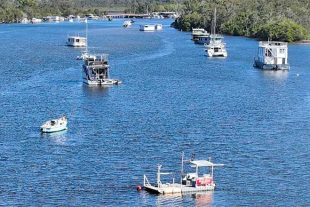

We met at the Grand Hotel boat ramp and quickly attracted a crowd of keen onlookers.

After a few photographs, we launched the boats and started going through the procedures that Rod always carries out – checking that everything on board works including all the pumps, lights and switches.

He checks on the motor and fuel system, batteries and electronics, then we do several tests on the water – recording engine revs, speed and fuel consumption to make sure that everything is within the manufacturer specifications.

It was a beautiful day and as we headed towards the Seaway, we noticed there was a slight swell around 0.5-1m with about 0.5m of chop on the top.

We headed out, testing the boats seakeeping ability and stability as we easily cut through the waves.

The ride was incredibly soft as always and particularly dry due to the hull shape of these vessels.

On top of that, there was also an unbelievable feeling of safety, being surrounded by an extremely well designed and manufactured cabin and of course the ballast system that works when the boat is at rest, holding water in its hull and releasing it quickly when the boat is underway.

This ballast system has a level of stability like no other boat I’ve been on and, even in considerably rough conditions, it sits level.

It’s extremely effective when two or three people want to stand on one side of the boat together because the boat does not attempt to tip at all.

All of the functions on the three boats were tested.

We ran the sonar and radar units that had been mounted and installed, we filled the live bait tanks to check for leaks and after we had completed all the tests in rough water, we headed to the smooth water south of Wavebreak Island.

It was here that we started to carry out the performance tests, where we measure the motor revolution and speed to ensure the boats are propped correctly and run most efficiently.

Two of the vessels were fitted with Mercury 200hp V6 outboards and the blue vessel was fitted with the 200hp V8 outboard.

All three vessels performed extremely well, with an average top speed of around 75-80km/h, depending on how many passengers were on board at the time.

The noticeable difference was the amount of torque that the V8 had over the V6 version.

Though both motors are 200hp, the V8 had an absolutely incredible hole shot and was able to get the boat on the plane within only a couple of seconds.

Over 100m standing start, the V8 version was 10-20m in front of the V6.

Fuel economy on the boats was also incredible, and with such big motors – the V6 200hp used a little less fuel of course – they certainly weren’t going to break the bank, with the best fuel consumption averaging around about 1.5-1.7L/km.

The boats we tested had been optioned up, but if you’re considering a Bar Crusher 670 Hardtop, they start at around $100,000 and work their way up – depending on the options and motor you choose.

Finally, after we had finished, we headed back to the boat ramp.

Retrieving the boats was made easy by the incredible design of the Easytow Trailers and the Bar Catch Winch, which allows you to simply aim the boat somewhere towards the centre and rear of the trailer and, as you gradually apply some forward thrust, the boat brings itself around from almost any angle and centres itself.

As you approach the winch bar on the trailer, the Bar Catch hooks the specially designed catch welded to the front of the boat and it’s safely connected to the trailer.

The entire launching and retrieving process of these big boats was incredibly easy and a one-person job.

These boats without a doubt have proven themselves as fishing weapons and are possibly the best custom and production plate aluminium boat I have been in.

To find out more information about these vessels, contact Rod Elliott at Australian Marine Centre on 07 3808 7333 or Bar Crusher Boats.

Bush ‘n Beach Fishing Magazine Location reports & tips for fishing, boating, camping, kayaking, 4WDing in Queensland and Northern NSW

Bush ‘n Beach Fishing Magazine Location reports & tips for fishing, boating, camping, kayaking, 4WDing in Queensland and Northern NSW