IF you’re bored one afternoon and looking for entertainment, a sure-fire way of starting a lively debate is to ask a group of paddlers which material is better: fibreglass or plastic.

Drop this one little question and then stand back and watch the fireworks. Of course, an engineer would tell you it’s an irrelevant argument because they both are in fact made of plastics. Either polyethylene or ABS for the ‘plastic’ boats or glass-reinforced polyester resins for the fibreglass ones, but that isn’t going to stop our group of paddlers arguing. So, for the rest of us, here is a short overview of the differences between the two and the pros and cons of each. Let’s start with what are commonly referred to as plastic canoes and kayaks.

Two main types of construction are employed for plastic canoes and kayaks – rotomoulded polyethylene and thermoformed ABS. By far the most common is rotomoulded PE, and it is the one we will discuss in detail here. Medium-density, linear polyethylene is a wonderful material. When used in its most common application, rotomoulding, it produces a reasonably stiff, durable and abrasion-resistant product that forms well into complex curves and is recyclable and repairable. Canoes and kayaks made from this material will exhibit good impact resistance and provide robust, durable boats with an excellent lifespan.

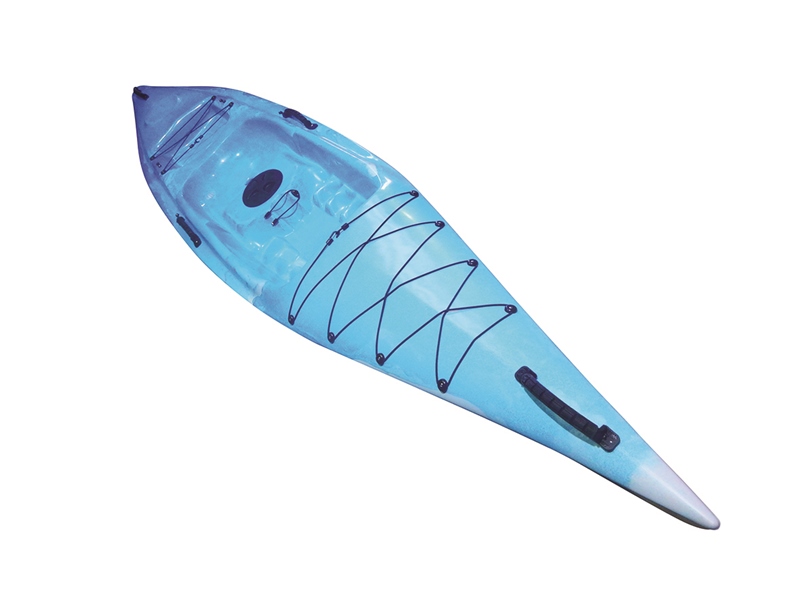

Rotomoulding, the most common manufacturing technique, is a well-established method of forming complex shapes in PE. It involves heating a metal mould in a gas-fired oven and slowly rotating it to allow beads of coloured PE to melt and run into the contours of the mould. It is relatively low cost and quite a forgiving process able to be performed by semi-skilled workers. Hence its attractiveness for mass producing the many sit-on kayaks available today.

It produces a consistent product and suits complex shapes and the addition of accessory fitments such as nut inserts. The key to the success of rotomoulded PE is its flexibility. This property allows it to give slightly when under impact and prevents it from cracking or chipping as stiffer materials tend to do. The downside of this is reduced stiffness in the flat panels of the boat. Reduced stiffness allows flexing of the hull while paddling, which causes excessive drag and stops it gliding through the water.

The answer most manufacturers have to excessive flexibility is to either increase the thickness of the hull or introduce ribs into flat panels. Both these solutions bring additional weight, and in the case of the ribs, additional wetted surface area. Hence the most common complaint about PE boats is their weight. A typical 3m rotomoulded PE boat can weigh in excess of 25kg. Something to be aware of with rotomoulded PE canoes and kayaks is they struggle somewhat with cut and gouge resistance.

Dragging your craft across a rocky beach or rubbing over submerged objects will deeply score the hull, leaving it with little fuzzy cuts on the bottom. Over time, these cuts will significantly increase hull drag and make your craft noticeably slower. Being a heat-formed product, PE boats are also affected by the sun and will start to deform if left sitting in the same position for extended periods. It’s quite common to see an older plastic sit-on kayak with a series of waves along its bottom.

In summary, kayaks and canoes made from rotomoulded PE will give great impact resistance and provide long reliable service, especially if stored properly and not dragged over sharp objects. They will however be significantly heavier than other construction types and be somewhat slower than an equivalent fibreglass boat.

And now let’s discuss composite or fibreglass canoes and kayaks. The manufacture of composite canoes and kayaks basically involves encasing a fabric mat in a liquid resin matrix. Once the resin sets, the resulting material benefits from the tensile strength of the fabric (resistance to pulling) and compressive strength of the resin (resistance to crushing), much the same as steel reinforcement in concrete. The most commonly used combination is a mat made from glass fibres encased in a polyester resin. Hence the commonly used term ‘fibreglass’.

Many other combinations of fabrics can be used, notably Kevlar and carbon fibre, but fibreglass is the most common and the type we will focus on here. Developed back in the 1950s, fibreglass was created as a means to make complex parts that had high strength and stiffness. Glass, when drawn out in a fibre, is an incredible material. It is relatively cheap to produce and has a higher specific tensile strength than steel, with a much lower weight. When encased in a polyester resin, with its high compressive strength, the two materials work together to form a lightweight composite that is both rigid and strong.

Canoes and kayaks made from fibreglass will weigh less than a comparable PE boat and have significantly higher hull stiffness. The most common and usually most economical way to manufacture fibreglass canoes and kayaks is to wet lay them in an open mould. In this process, the boat is built from the outside in, with the outer coating or layer being the first part of the craft to be put into the mould. Usually this layer is a special type of resin called gelcoat. The gelcoat contains silica powder and is harder and more abrasion resistant than regular laminating resin.

On top of this initial layer are placed the layers of fibreglass mat, each one completely coated in polyester resin to bond it to the others. Once cured, these layers set together to form a strong, light and durable laminate – perfect for constructing canoes and kayaks! A typical 3.6m fibreglass kayak can weigh as little as 12kg.

As with the rotomoulded PE, with the good comes the bad. Fibreglass is excellent for boat building because it is stiff and light, however the hard and stiff construction also means it is somewhat brittle and can crack under heavy impact. The good news is fibreglass is very easy to repair and when done professionally leaves little trace of the previous damage. Fibreglass craft, as a rule, are more expensive than comparable PE canoes and kayaks. This is due to the higher labour content required in manufacturing. The trade-off is the finish quality of fibreglass is arguably higher given the mirror-like surface achieved from spraying gelcoat into a mould. It’s this mirror-like finish that makes fibreglass boats glide over the water.

In summary, canoes and kayaks made using fibreglass are light, strong and stiff. They will glide on the water due to their mirror finish and stiff hull and the gelcoat outer layer will tend to maintain its surface finish after years of use. In addition, fibreglass allows manufacturers to achieve sharp edges and crisp lines, giving designers more ability to create boats with superior performance. They will, however, require more care in areas where impact damage may be prevalent and will not stand up to the outright abuse a PE boat will. Having said that, don’t be led to believe fibreglass boats are fragile.

The laminated structure used in their manufacture is extremely strong and when combined with fabrics such as Kevlar they are superior to most modern materials. So, what should you choose? The great debate…

At the end of the day, the choice comes down to the individual paddler. If you want a canoe or kayak that can take a real beating and you aren’t concerned about performance, then choose a rotomoulded polyethylene boat. But if you want a canoe or kayak that will glide almost effortlessly through the water and maintain its performance over many years of service, then a fibreglass boat is the one for you. Your best bet is to beg, borrow or hire a few different types and decide for yourself. If you’re still not sure, call the helpful staff at Natureline Australia for some advice on 07 3390 4106 or visit onetreecanoe.com

Happy paddling!

Bush ‘n Beach Fishing Magazine Location reports & tips for fishing, boating, camping, kayaking, 4WDing in Queensland and Northern NSW

Bush ‘n Beach Fishing Magazine Location reports & tips for fishing, boating, camping, kayaking, 4WDing in Queensland and Northern NSW